Floor jacks and jack stands work together to lift and support vehicles so people can work under them safely. A good setup raises the car to a steady height, holds it without shifting, and fits under low bumpers and frames. The right choice makes basic jobs like oil changes, brake service, and tire work feel simple and predictable.

The model you pick affects safety, setup time, and how much effort each lift takes. Capacity, lift range, profile, and stand height all need to match your vehicles and work area.

This guide looks at some of the best floor jacks and jack stands models and highlights the key features that help you match them to your cars, space, and budget.

What are floor jacks and jack stands?

A floor jack is a wheeled hydraulic jack you use to raise part of the car off the ground. Jack stands are sturdy, adjustable supports you place under the vehicle after lifting it. The jack does the lifting, and the stands take over to hold the weight while you work.

Each jack stand has a wide base and a support post you can raise to the height you need. Look for stands rated at least three-quarters of your vehicle’s weight, and place them at the proper support points.

Safety agencies warn that hydraulic jacks are for lifting only and say you should always secure the vehicle with jack stands or blocks before working underneath. After you lift the car with the floor jack, place the stands at the recommended jack points, lower the car gently onto them, and check that everything is stable. Never rely on a floor jack alone to support a vehicle. People use this setup for jobs like changing tires, inspecting brakes, or doing oil changes at home.

Scissor jacks vs. floor jacks vs. bottle jacks

Scissor jacks, floor jacks, and bottle jacks all lift vehicles, but they work in different ways and suit different jobs. A scissor jack uses a screw and crossed metal arms to raise the car. You turn the handle and the arms close like scissors, which lifts the vehicle a short distance. These jacks are compact and light, so many cars include them for roadside tire changes. They usually have lower weight ratings and are slower to use.

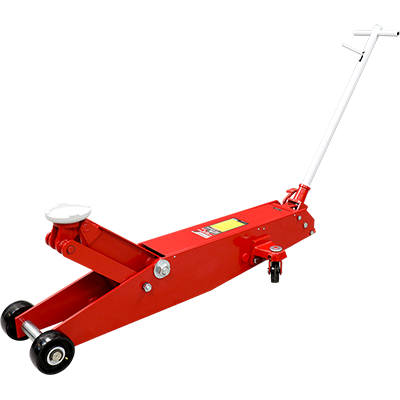

A floor jack is a hydraulic jack on wheels with a long handle and a wide frame. You pump the handle and a horizontal cylinder lifts a pad under the car. Floor jacks roll easily, feel stable, and often have a larger lifting range. They work well for home garages and repeated maintenance.

A bottle jack is a vertical hydraulic jack with a narrow base and a tall cylinder. You pump a small handle and a piston rises straight up. Bottle jacks are compact, support very heavy loads, and can often lift higher than a floor jack, which helps with trucks, SUVs, and other high vehicles. Their tall shape and higher minimum height can make them less stable under small, low cars.

In general, use a scissor jack for emergencies, a floor jack for regular home work, and a bottle jack for heavy, tall vehicles.

Best floor jacks and jack stands

Choosing the right floor jack and jack stand depends on your vehicle mix, lift height needs, and available workspace. Here are some top manufacturers and brands to consider.

- Ranger

Ranger floor jacks and jack stands give garages a safe and reliable way to lift and support vehicles. Ranger floor jacks handle many types of vehicles, with quick-pump and low-profile models that lift about 3,000 to 60,000 pounds. They are built from strong steel for long-term durability and smooth hydraulic operation.

Each model focuses on strength, stability, and easy handling for everyday shop use. They use welded steel frames, wide bases, and ratchet-and-pin locks to hold weight safely. Models range from 3-ton to 12-ton capacities, with high-reach versions for taller vehicles. Together, Ranger jacks and stands form a simple, safe setup for nearly any service bay, supported by helpful manuals, product support, and financing options.

Pros:

- Heavy steel construction and sealed hydraulics support longer service life

- Built-in overload valves prevent lifting loads that exceed the rating

- Swivel casters improve ease of movement when positioning the jack under a vehicle

- Welded steel bodies and wide bases increase stability under load

- Multiple capacities and high-reach options accommodate different vehicle sizes and tasks

Cons:

- Release/valve control feels imprecise, making lowering the lift tricky

- Jack’s action is jerky and uncontrolled

Best for: Shops that need one brand to handle both low-clearance cars and heavier trucks with matching lift and support equipment.

Learn more about Rangers Floor Jacks/Jack Stands.

- Blackhawk

Blackhawk floor jacks lift vehicles using hydraulic power. Models range from 3-ton capacity (for smaller cars) to high-lift versions for heavier loads. They offer features like bypass protection on the hydraulic system and metered release for controlled lowering. Blackhawk jack stands come in multiple ton ratings and use welded steel constructions. Stand heights adjust via ratchet or pin systems to match different vehicle types

Pros:

- Fast-lift mechanisms help reduce strokes needed to reach the load point

- Bypass devices help protect internal hydraulic components during lifting

- Internal safety valves and vent plugs help support safe operation

- Metered release systems help provide more controlled lowering

Cons:

- Release sticks slightly, so smooth, slow vehicle lowering becomes tricky

- It is difficult to carry or move

- It takes too many pumps to jack up a car/truck

Best for: Home garages and light-duty shops that want steel service jacks and matching stands.

- Husky

Husky floor jacks use hydraulic pressure to lift vehicles up to about 6,000 pounds, with models that reach roughly 18 to 21 inches in height. They use heavy-gauge or steel-and-aluminum frames, four casters, and a swivel saddle to move under the vehicle and line up the lift point. Husky jack stands use a steel base, anti-sink feet, and an iron saddle with extended reach. They come in pairs and support SUVs, light trucks, and cars.

Pros:

- Low-profile designs reach under many lower cars and small SUVs

- Steel or hybrid frames provide strength while keeping overall weight manageable

- Wide steel bases and anti-sink feet deliver stable placement on varied surfaces

- Secondary safety pins on some stands offer added mechanical locking

Cons:

- Release can be hard to control, so lowering becomes less precise

- Quality control issues appear common, so reliability may be inconsistent

Best for: Home garages and DIY users who need basic steel jacks and stands for typical cars, SUVs, and light trucks.

- Pro-Lift

Pro-Lift floor jacks use a hydraulic trolley design to raise one end of a vehicle. A common 2-ton model lifts from about 3-5/8 to 13-3/8 inches and has a 4,000-pound capacity. It uses heavy steel construction, casters, and a swivel saddle, and includes a bypass system that limits overloading. Pro-Lift jack stands, such as the 3-ton double-pin type, use stamped-steel bases, cast-iron ratchet bars, double locking pins, and adjustable height to support partial vehicle loads at one end of the vehicle.

Pros:

- Many models provide lift ranges that cover typical passenger vehicles

- Swivel saddles and casters allow easier jack positioning and movement

- Several products list compliance with ANSI or PALD safety standards

- Release handles or pins lock each stand securely at height

Cons:

- The jacks have a thick powder coat that flakes and chips off

- Wide gaps between setpoints make finding correct jaw height difficult

- Narrow, sharp feet dig into asphalt under load

Best for: Budget-conscious users who want basic, ANSI-compliant jacks and stands for light-duty service on typical passenger cars and small SUVs.

- Powerbuilt

Powerbuilt floor jacks include standard hydraulic garage jacks, Triple Lift models, and Unijack bottle jacks that also act as stands. Capacities in this group run from about 3,000 to 6,000 pounds, with lift ranges between 8½ and 21 inches, depending on model. Some units use removable saddles, padded lift rails, or a locking safety bar to hold the load. Powerbuilt jack stands and ratcheting Unijack designs provide support at set heights for cars and light trucks.

Pros:

- Wide wheelbases and flanged frames improve jack stability on uneven ground

- Locking safety bars support vehicle loads without separate jack stands

- Ductile iron ratchet masts provide roughly ten discrete height settings

- Most models meet current ASME safety standards

Cons:

- Jack malfunctions while lowering and leaks hydraulic fluid during adjustment

- Safety pin does not function as intended

- Customer service is unresponsive and difficult to reach

Best for: Home garages and car users who want all-in-one jacks that lift and support typical cars, SUVs, and light trucks with fewer separate tools.

- Torin

Torin floor jacks use hydraulic systems to lift vehicles in the 2 to 3 ton range, with lift heights from roughly 5.5 to 20 inches. They use steel frames, casters, and overload or bypass valves that limit use beyond the rated capacity. Torin jack stands support the vehicle after lifting, with 3 ton pairs that adjust between about 11 and 17 inches. They use forged steel, ratchet bars, double locking pins, and wide pyramid bases.

Pros:

- 360-degree swivel casters provide easier positioning and maneuvering

- Heavy-duty steel construction provides durability for repeated lifting tasks

- Wide pyramid bases provide broader load spread and stability

- Multi-position ratchet bars provide quick locking height adjustments

Cons:

- Too small for regular vehicles, especially larger models

- Lacks a safety bolt, so confidence in primary support is low

- The tool leaks hydraulic oil

Best for: Value-focused buyers who want a wide range of steel floor jacks and jack stands for passenger cars, SUVs, and light trucks.

- Vevor

Vevor floor jacks use a hydraulic pump to raise vehicles. A common model has a 3-ton (6,600 lb) rating, a steel body, a low profile, and a lifting range of about 130 to 500 mm for cars, SUVs, and light trucks. Vevor jack stands have 3-ton capacities, adjustable height around 10.8 to 16.3 inches, and wide pyramid bases. They use carbon steel and cast iron parts with double locking ratchet and pin mechanisms.

Pros:

- Dual-piston pumps raise vehicles using fewer handle strokes per lift cycle

- Four wheels support easier movement around the work area

- Carbon steel bases and cast-iron bars increase overall durability

- Double-locking systems combine ratchets and separate safety pins for extra security

Cons:

- The quality of the metal is cheap and thin, plus there is no pin on the safety bar

- Ratchet stops, and arms are not welded perfectly, and have less engagement

Best for: Buyers who want low-profile hydraulic jacks and double-locking stands for typical cars, SUVs, and light trucks.

What to consider when adding a floor jack to your shop

When choosing a floor jack, here are some factors to consider:

Load capacity

Start by checking the gross vehicle weight rating (GVWR) on the label inside the driver door. Pick a floor jack with a rated capacity that clearly exceeds the heaviest vehicle you plan to lift. Many techs add a 25 to 50 percent safety margin. You often lift only one end of the vehicle, but the jack still needs generous capacity to stay stable and within its limits.

Plan for future heavier trucks and match your jack with stands that meet or exceed the same rating.

Lift points and range

When you add a floor jack to your shop, start with the lift points on the vehicles you service. Check the owner’s manual and frame diagrams so you know where the jack pad must reach without touching plastic trim or rusted edges. Then match the jack’s lift range to your work.

A low minimum height helps with lowered cars. A higher maximum height helps with trucks and stands.

Portability and storage

When you add a floor jack to your shop, think about how easily you can move it and where you will store it. Portability starts with weight, wheel design, and handle length. A lighter jack with smooth rolling casters and a long handle is easier to move between bays or around tight spaces.

For storage, look at the jack’s footprint, height, and handle removal. Make sure you have a stable spot on the floor or a rack where it stays dry, clean, and out of walkways.

Height range

When you add a floor jack to your shop, the height range matters a lot. Check the minimum height first. The jack should slide under your lowest car, even if a tire goes flat. Then look at the maximum height. It must lift the vehicle high enough to place jack stands at a safe working level.

Find the best floor jacks and jack stands with Wrenchers

Choosing the right floor jack and jack stands is a key safety decision for any shop. Many tools look similar, yet they differ in capacity, lift range, profile, and base design. The best setup fits your vehicles and the jobs you run most often. A good combination slides under low cars, lifts high enough for stands, and supports the rated weight of every vehicle you service. Clear controls and stable bases help techs use the tools consistently.

Wrenchers offers a wide selection of floor jacks across capacities—from standard 3-ton models to heavier 30-ton units—so you can pick what matches your service vehicles. They also list jack stands in various tonnage ratings, with adjustable height and different designs to support compact cars up to larger trucks.

Explore Floor Jacks and Jack Stands with Wrenchers.

Floor jacks FAQs

What maintenance is required for a floor jack?

To maintain a floor jack, start by doing regular visual checks for cracks, damage, or loose parts. Wipe off dirt and grease and keep wheels and pivots clean. Inspect for hydraulic fluid leaks around seals and fittings. Check the fluid level, top up with the correct oil, and bleed air if the jack feels weak or spongy. Lubricate moving parts such as the handle, hinges, and casters. Store the jack lowered, unloaded, and in a dry, clean place, and follow the maker’s service schedule.

What is a dual-piston floor jack?

A dual-piston floor jack is a hydraulic floor jack that uses two pump pistons instead of one. Each time you move the handle, both pistons push fluid into the main cylinder, so the lifting pad rises faster with fewer strokes. Dual-piston or dual-pump jacks can lift a vehicle several times faster than similar single-pump jacks, which saves time and reduces effort when raising cars, SUVs, or light trucks.

Are jack stands necessary for using a floor jack?

Yes. Safety agencies and automaker guides say you should always use jack stands when you work under a vehicle that you lifted with a floor jack. A hydraulic floor jack can fail, leak, or move, even on a flat surface, so it should only lift the vehicle, not hold it in place. After you raise the car to the right height, set jack stands at the proper support points, lower the vehicle onto them, and then remove the jack.